VFDs with built-in PLCs offer an efficient and effective method to create processes for pumping systems.

PLC insights

- VFDs with integrated PLCs are transforming pumping systems by combining intelligent automation with advanced motor control, ensuring efficient operation while protecting equipment from common failures.

- As PLC technology becomes more integrated into modern VFDs, these systems simplify setup, enhance redundancy, and optimize energy efficiency across industries such as water treatment, oil and gas and HVAC.

- The associated setup wizards make these VFDs excellent choices for safe and reliable systems that are easy to commission.

Variable frequency drives (VFDs) with integrated programmable logic controllers (PLCs) and specialized pumping software are revolutionizing the operation of pumping systems. By guaranteeing effective operation to satisfy fluctuating demand, these integrated solutions offer a simplified method of protecting equipment.

Complex pumping applications are made more reliable and efficient by these systems, which combine the power of intelligent automation and superior motor control into a single device, the VFD.

Integrated PLCs are becoming a common element of many contemporary drives as VFD technology develops further. Because the user can program these PLCs to direct the functions of VFD, they can be customized for a variety of uses. Additionally, manyvendors offer preprogrammed setups for particular use cases, such as multiplex pumping systems.

These preprogrammed application wizards simplify the VFD-to-PLC integration and allow for precise control and coordination of multiple pumps, enabling systems to respond dynamically to changing demands. This capability is particularly important in sectors where demand changes are frequent and operational efficiency is crucial, like water and wastewater treatment, oil and gas and HVAC.

Advantages of VFDs with integrated PLCs

Simplified setup and operation: Traditionally, PLCs separate from the VFDs were used for these types of systems. Having aseparate PLC often leads to an increase in complexity and costs. Creating systems like these from scratch requires engineers, users and installation technicians to have knowledge of the VFDs, PLCs and the details involved in creating safe and effective pumping systems.

Additionally, when the system is designed using a separate PLC, this creates a single point of failure situation. If the PLC were to fail or stop operating for any reason, the system would be inoperable until the PLC was repaired or replaced.

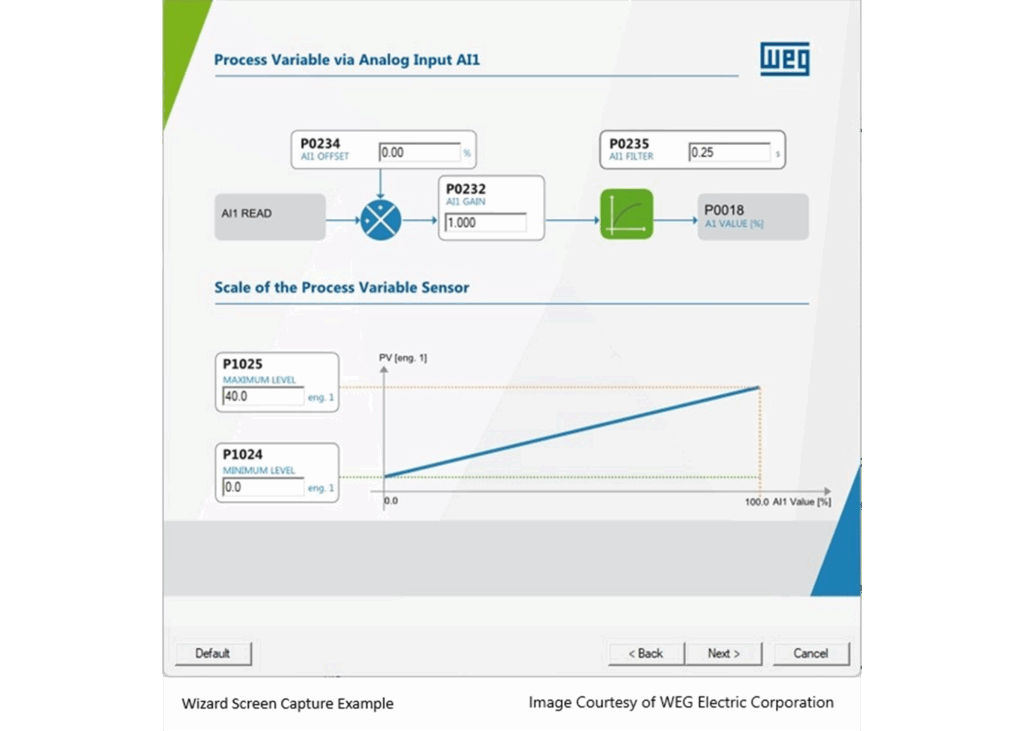

In comparison, modern VFDs with integrated PLCs can transfer primary control of the system to one of the other VFDs and the system can continue to operate and effectively eliminate a single point of failure scenario. In terms of installation ease, the VFDs feature intuitive setup wizards and pictorial graphics that guide users through the configuration of the pumping system, taking into consideration the number of pumps, pump speeds, pump protections and proportional-integral-derivative loop tuning. This reduces the complexity typically associated with programming and commissioning, making these systems accessible even to those with limited technical expertise.

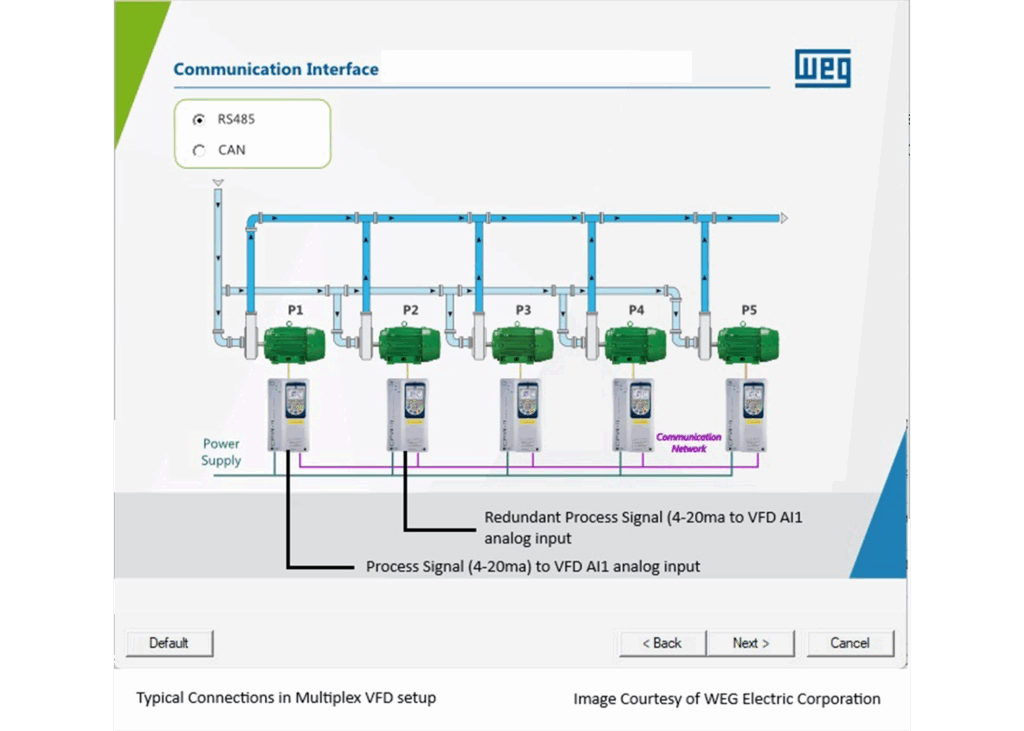

In terms of hardware, the analog and digital input/output that are part of the VFD are used instead of additional PLC equipment. The analog inputs on the drive served as input for the process signal (flow, pressure, level) and the digital inputs can be used with auxiliary switches.

The primary drive accepts the process signal, controls the process and directs the other drives when to run and at what speed. The connection between the primary drive and the other drives is via a communication protocol.

For backup redundancy, a duplicate process signal can be connected to one of the other drives so that if there is a loss of signal to the primary drive or the drive faults, the second drive can take over immediately as primary to run the system.

Enhanced equipment protection: These systems offer a variety of configurable protection features to safeguard both pumps and the overall system. Among the primary protection features are:

- Preventing pump cavitation: Making sure pumps run without air gaps that can damage pumps due to low pressure at the pump’s suction end.

- Water hammer mitigation: Increasing the system’s longevity by lowering pressure surges that harm pipe elbows and fittings.

- Suction/discharge pressure loss detection: preventing dry running and guaranteeing stability of operation.

- Seal water and check-valve integration: Supporting auxiliary components to maintain reliable operation.

- Seamless control transfer: Allowing standby VFDs to take over system control without interruption.

Optimized efficiency: To optimize energy efficiency, these VFD/PLC systems run pumps at the most effective speeds depending on real-time data from sensors. This minimizes environmental effects and lowers energy usage, which not only lowers operating expenses but also helps sustainability programs.

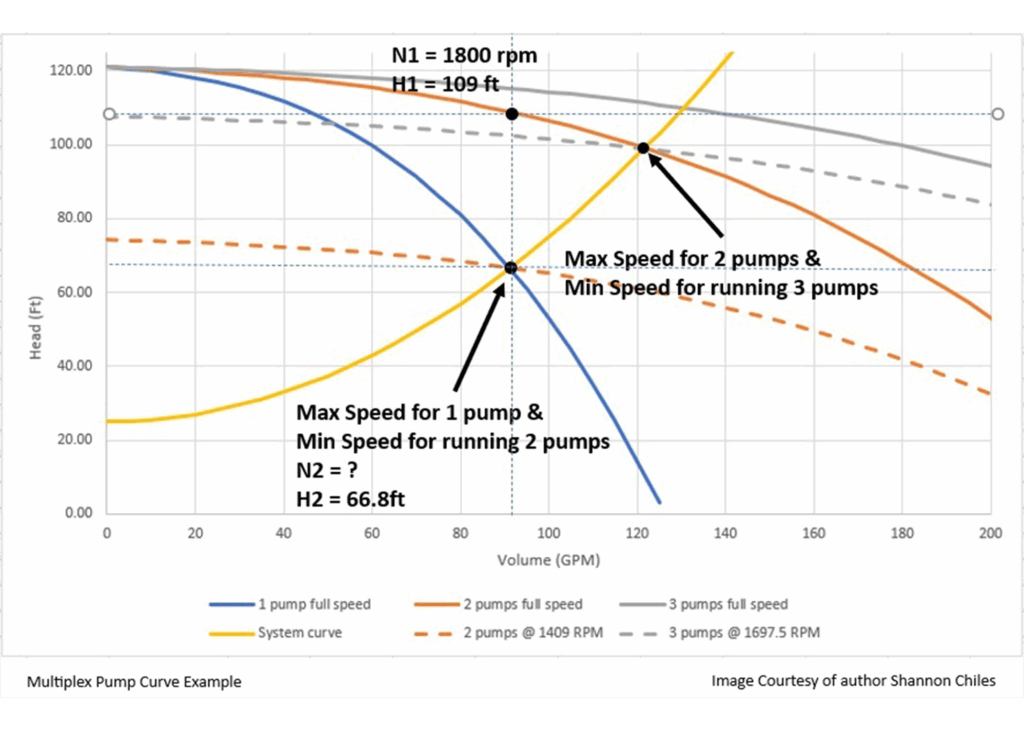

Additionally, by proper use of pump curves and affinity laws, minimum pump speeds can be determined to maximize flow and reduce wasted energy.

In the above example, we can use the affinity law relating head to speed. That formula is:

H1/H2 = (N2/N1)²

Because we are looking for N2, the formula can be rewritten as:

N2=N1/√(H1/H2)

Where:

H = head

N = speed

By plugging in our values, we find that two pumps running at 1,409 revolutions per minute (rpm) pumping the same volume as onepump running at 1,800 rpm at the point of intersection with the system curve. When the minimum speed value for two pumps running is entered into the integrated VFD pumping system, the system then operates at maximum efficiency without a decrease in volume. The same type of calculation can be done for the above to find out the minimum speed required when running three pumps.

Applications of VFDs with integrated PLCs

Water and wastewater management is one of the most well-known uses for VFDs with integrated PLCs. Municipalities rely heavily on pumping systems for city water treatment and distribution as well as wastewater processing. These systems are subject to varying flow demands, which makes efficient and reliable operation crucial. Integrated VFD-PLC systems provide:

- Demand-based control: Adjusting pump speeds to match real-time demand, reducing energy waste.

- Leak detection and prevention: Monitoring system pressure and flow to identify potential leaks or blockages.

- Redundancy management: Coordinating multiple pumps for seamless transitions in case of equipment failure.

High-rise building water booster pumps: Maintaining adequate water pressure for occupants of high-rise buildings is common use for VFDs with integrated PLCs. These buildings could be hotels, office buildings, dormitories or a variety of commercial use structures. Systems in this application provide:

- Water pressure consistency: By monitoring system water pressure, the number of pumps running and the speed that they are running can change to maintain a set pressure throughout the building.

- Energy efficiency: Since pumps only run at the required rate to maintain pressure, energy is saved and lowers electricity consumption.

- Remote monitoring: Allowing operators to monitor and adjust operations from central control rooms or remote locations.

In the oil and gas sector, VFD/PLC systems play a vital role in upstream, midstream and downstream operations. From extraction to refining, these systems ensure:

- Flow control: Maintaining precise flow rates to optimize production and processing.

- Pressure regulation: Preventing over-pressurization in pipelines and equipment.

- Remote monitoring: Allowing operators to monitor and adjust operations from central control rooms or remote locations.

Heating, ventilation and air conditioning systems also benefit significantly from VFD-PLC integration. These systems are used in commercial buildings, data centers and industrial facilities to:

- Regulate airflow: Adjust fan and pump speeds to maintain desired temperature and humidity levels.

- Improve energy efficiency: Minimize energy consumption during periods of low demand.

- Enhance system longevity: Reduce wear and tear on components by operating at optimal speeds.

Challenges and considerations of built-in PLCs

Although VFDs with built-in PLCs have many benefits, there are also some challenges to their deployment. Organizations should consider technical expertise and compatibility and integration.

Although modern systems are designed to be user-friendly, organizations may still require skilled personnel for programming and troubleshooting. Procuring training and support services from the manufacturer is essential in bridging this gap.

Ensuring compatibility with existing equipment and systems is critical. Careful planning and consultation with manufacturers can help mitigate potential issues during installation.

Future trends in VFD-PLC technology

Future developments in digitization and connectivity will influence the use of VFDs with built-in PLCs. Among the new trends are:

- Internet of things integration: Enabling real-time monitoring and control via cloud-based platforms.

- Advanced analytics: Leveraging data to predict maintenance needs and optimize system performance.

- Sustainability features: Incorporating renewable energy sources and energy recovery mechanisms as well as AI learning to optimize system usage.

A major advancement in pumping system technology is represented by the combination of VFDs with integrated PLCs and sophisticated pumping software. These systems offer a dependable and economical solution for a variety of applications by fusing energy-efficient operation, strong protective features and ease of use. This technology is a great option for today’s pumping problems because it can result in improved operational performance, less downtime and long-term savings.

A key component of dependable system design is the capacity to adjust to shifting needs while safeguarding vital assets, whether inindustrial operations or water management. VFDs with integrated PLCs are expected to become even more crucial in promoting efficiency and innovation in pumping systems as a result of continuous technological breakthroughs.