The Plant Engineering audience read articles covering condition monitoring, generative AI and attracting younger workers in the month of May. Discover insights on these topics and more with our top 10 articles here.

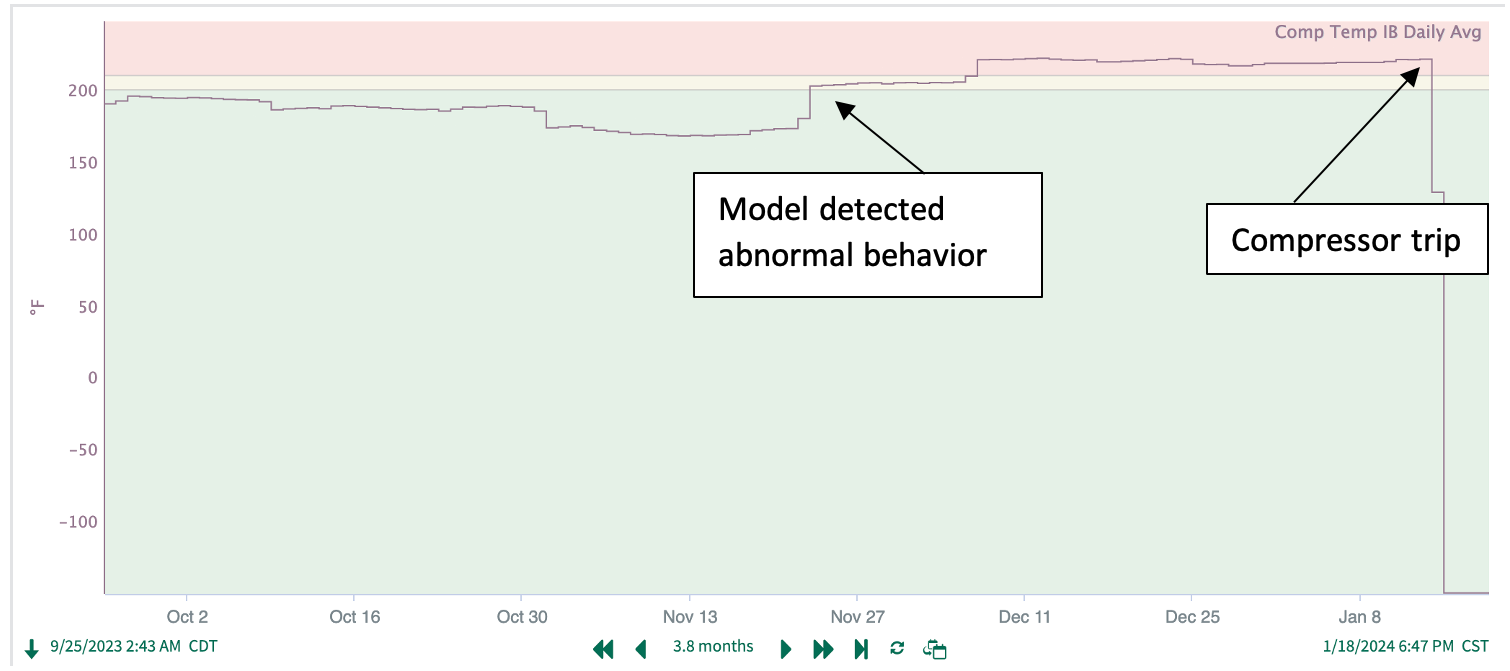

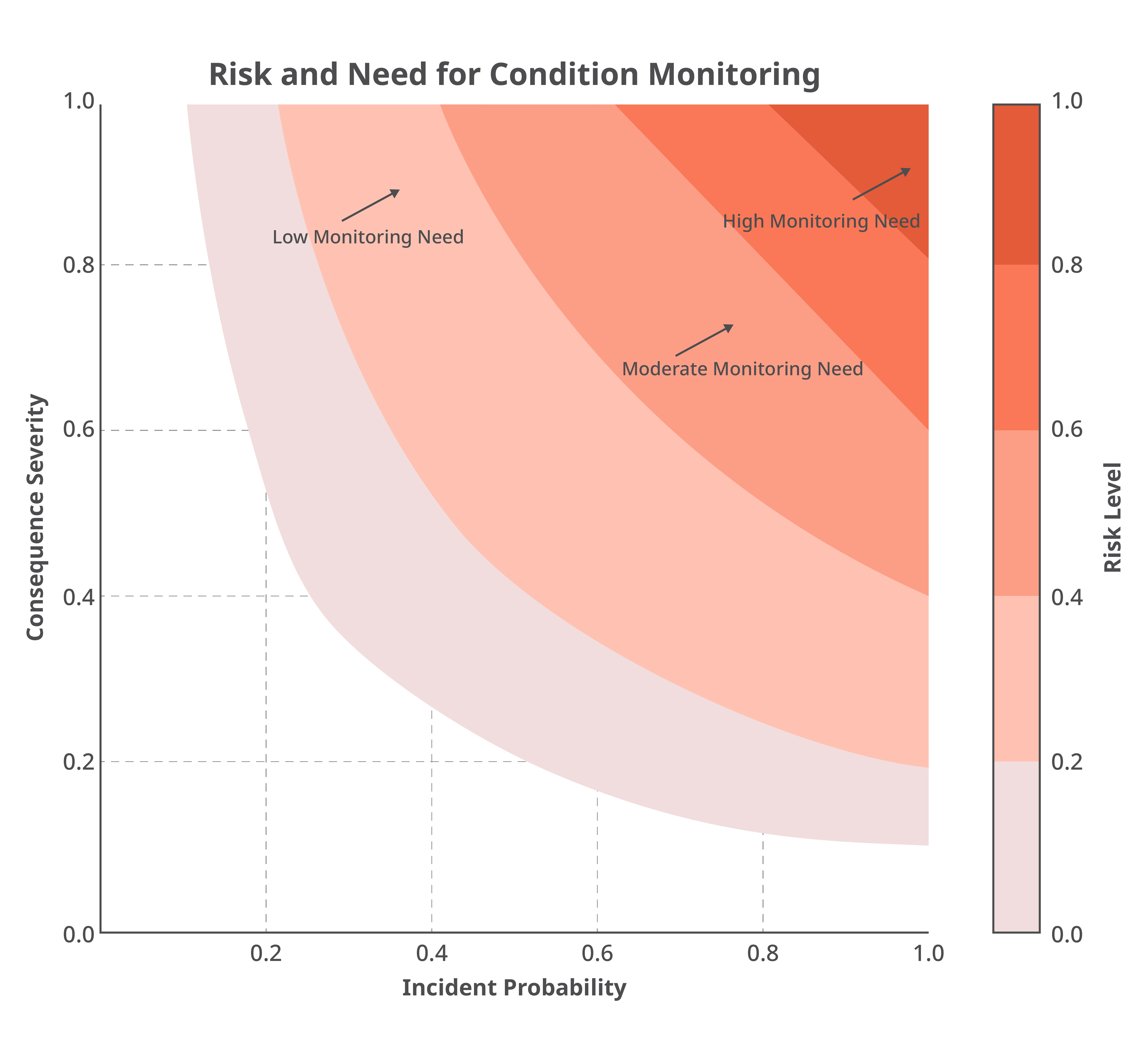

1. Need a condition monitoring program to thrive? Start by planning

Being intentional about goals when developing a condition monitoring (CM) project roadmap leads to earlier wins and long-term success.

2. How to use generative AI for plant maintenance in six steps

Generative artificial intelligence (AI) is transforming predictive maintenance by improving failure predictions, optimizing workflows and creating a self-improving system that enhances asset reliability and efficiency.

3. Manufacturers grapple with an age-old problem – attracting Gen Z workers

There’s been a push to reshore manufacturing jobs to the U.S. But manufacturers are struggling to hire Gen Z workers even as their workforce ages. Are there practical ways to make manufacturing appealing to younger workers?

4. Know the best practices for emergency safety equipment compliance

Proper placement of emergency safety equipment is determined by OSHA regulations, industry guidelines and insurance requirements.

5. Three examples of intelligent energy management in industrial plants

Intelligent energy management solutions enable industrial operators to optimize energy use, reduce costs and enhance plant performance.

6. Experts reveal these maintenance trends you need to watch

This panel of experts reveals some of the top manufacturing maintenance trends. From artificial intelligence and machine learning to predictive maintenance, you’ll want to watch and implement these strategies.

7. How to use data analytics to develop a winning manufacturing strategy

Artificial intelligence-based tools provide remarkable insights leading to improvements in any domain that can be characterized with data.

8. Closing the gap: a practical guide to maintenance maturity

This guide breaks down the path to maintenance maturity, helping leaders understand where they stand today and what steps they can take to build a smarter and more efficient operation.

9. Trends to watch in the future of VFDs and motors

The use of VFDs is becoming mandatory because of many new motor designs. Watch these upcoming trends.

10. Do your plant hardware and software really integrate? How to make the most of data you have on hand

Learn how manufacturers can manage the balance between connectivity and the large capital expenditures to modernize and what plants will be able to do in the future as a result.